the possible reasons for the worn-out situation of diamond disc

the possible reasons for the worn-out situation of diamond disc

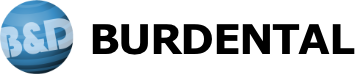

The quality of Diamond Disc is mainly up to the particle size of diamonds, which is one of the important indicators to test its wear resistance and sharpness. Once we use it improperly, it will be worn out. So what is the reason for this phenomenon? Today, let me share this knowledge with you.

The Possible Reasons for The Worn-out Situation

No.1 Quality issue: Speaking of the reasons for the worn-out situation of Diamond Disc, I believe many people know that this is mainly caused by the poor quality of the slices. If the strength of the slices is relatively low, the matrix is uneven. And this phenomenon will exist in the use process if the mental carcass doesn’t match with the slices. Even, if sparks appear when the cutter head is cutting, it means that the slightness of the product is bad.

No.2 Improper Usage: When we are using Diamond Disc for dry cutting, we cannot cut the items continuously within ten minutes. Otherwise, it will badly affect the service life and the effect of the slices.

No.3 Unfriendly Environment: Diamond Disc should be placed in a ventilated and dry place if it is found that its protection cover is damaged. Otherwise, the humid environment causes the water mist to enter the slice from the damaged cover and results in an oxidation reaction.

Therefore, in order to avoid this situation, we should pay attention to these common senses, so that we can better make use of it.

If you want to know more, please click our official website: https://www.burdental.com/diamond-disc-plaster-trimming-wheel

Blog

- the comprehensive guide to using finishing and trimming carbide burs in dentistry

- understanding dental burs: types, uses, and techniques

- understanding carbide burs: comprehensive guide to their uses and benefits

- beginner's guide to using nail drill bits

- how to choose the right nail drill bit for your needs

- the latest trends in nail drill bit shapes

- ergonomics for endodontists: avoiding pain and strain from handpieces

- endodontic handpieces of the future: a sneak peek at exciting new designs

- pimp my handpiece-unleashing style and performance in your endo tools

- dental sandblaster buyer’s guide