do you know the clamping and vibration of milling burs

do you know the clamping and vibration of milling burs

Hello everyone, so happy to see all of you again. It has been several days since we last shared an article about Milling burs. Now let us continue the left part, but please forgive that I only share what I have known. So welcome to comment if you don't mind.

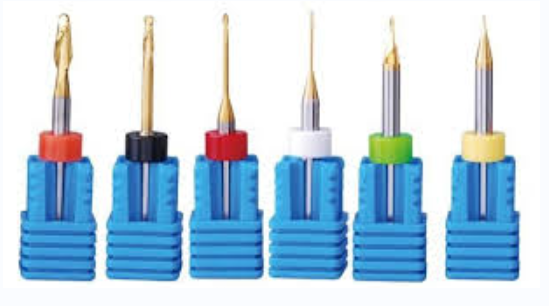

Clamping of Milling Burs

Most of the milling burs used in the machining center are in the form of spring clips and are in cantilever form when used. During the milling process, the milling bur may gradually protrude from the tool holder so it will be completely damaged. And the workpiece will also be scrapped, mainly resulting from the insufficient clamping force.

The milling bur is generally coated with anti-rust oil when it leaves the factory. If non-water-soluble cutting oil is used for cutting, a misty oil film will also be attached to the inner hole of the tool holder. Clamping the tool holder is difficult, and the milling bur will cause loosening and loss during processing. Therefore, before setting a milling bur, the shank of the milling bur and the inner hole of the cutter holder should be cleaned with cleaning fluid. So it should be dried before clamping.

The vibration of Folding Milling Burs

In CNC milling of workpiece cavities such as molds, it is necessary to lengthen the protrusion of the milling bur when the cutting point is a concave part or a deep cavity. If a long-edge milling bur is used, it is easy to generate vibration and cause the tool to break due to the large deflection of the tool. Therefore, it is best to use a short-edged and long-shank milling bur with a longer overall tool length in the machining process. When machining workpieces with large-diameter milling bur on a horizontal CNC machine tool, more attention should be paid to the balance of cutting speed and feed rate.

For more details please visit our official website: https://www.burdental.com/for-lab/cad-cam-milling-burs

Blog

- the comprehensive guide to using finishing and trimming carbide burs in dentistry

- understanding dental burs: types, uses, and techniques

- understanding carbide burs: comprehensive guide to their uses and benefits

- beginner's guide to using nail drill bits

- how to choose the right nail drill bit for your needs

- the latest trends in nail drill bit shapes

- ergonomics for endodontists: avoiding pain and strain from handpieces

- endodontic handpieces of the future: a sneak peek at exciting new designs

- pimp my handpiece-unleashing style and performance in your endo tools

- dental sandblaster buyer’s guide