- Home

-

Products

- Diamond Burs For Clinic

- Tungsten Carbide Burs

- Surgical Tungsten Carbide Burs

- Triming Finishing Gold Tc Bur

- Diamond Stones & Diamond Polishers

- Diamond Rubber Polishers

- Cleaning Burs After Debonding

- Silicon Polishers

- White Stones & Green Stones

- Polishing Brushes

- Mandrels

- Blocks, Sterilisable

- Clinic Kits

- Samples Collection

- Dental Equipment

- Dental Handpiece & Implant Bender

- Dental Mobile Photography

- Diamond Bur Hp

- Fully Sintered Diamond Bur Hp

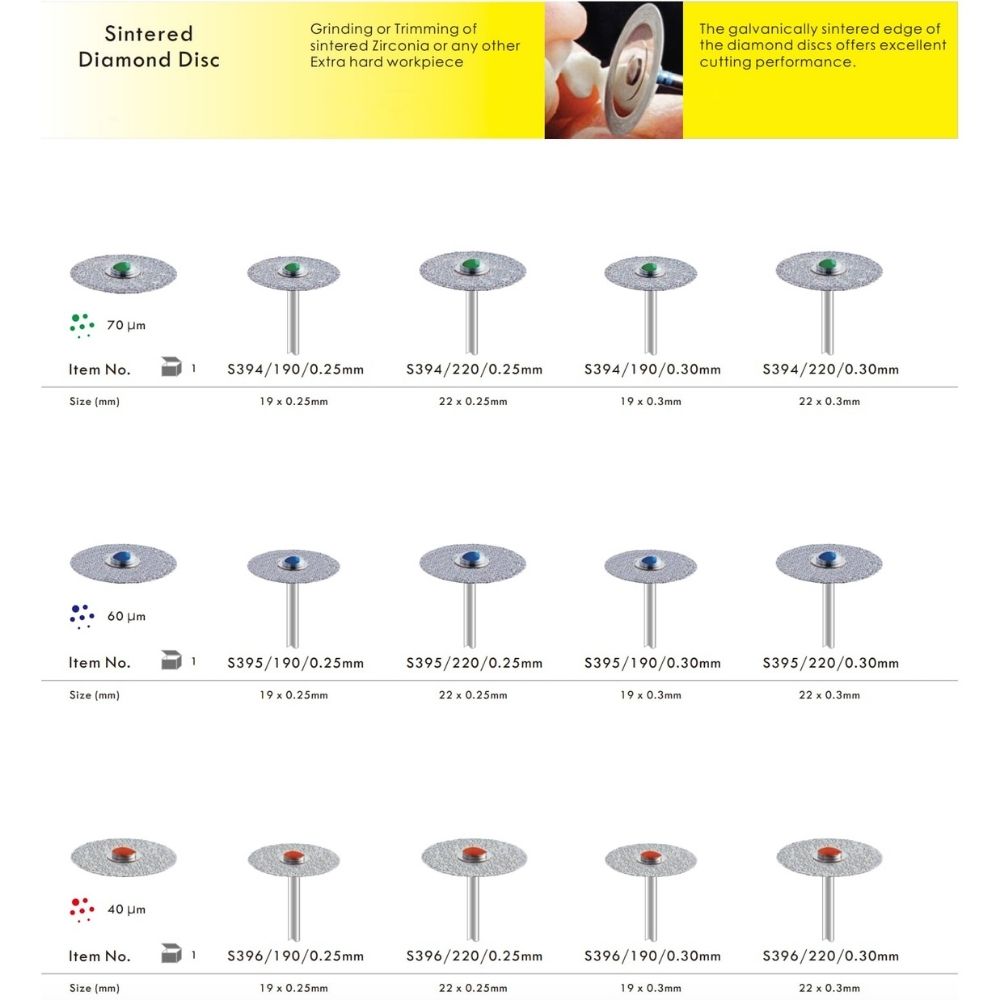

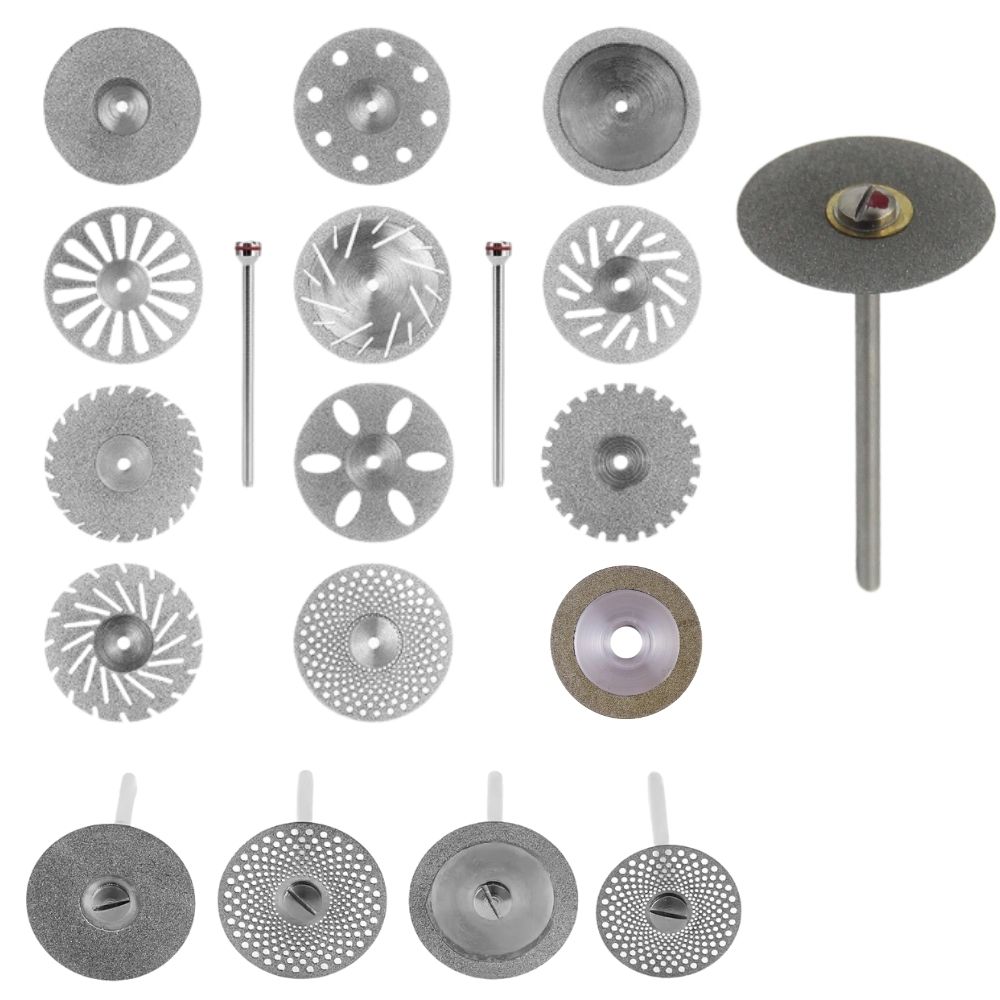

- Diamond Disc

- Plaster Trimming Wheel

- Cad/cam Milling Burs

- Tungsten Carbide Bur

- Tungsten Carbide Cutter Hp

- Tungsten Carbide Burs For Milling Machines

- Diamond Stones For Zirconia Or All Ceramics

- Diamond Polishers For Zirconia Or All Ceramics

- Silicon Polisher

- Silicon Polishing Burs For Composite Resins

- Mounted Stone

- Mounted Sandpaper

- Polishing Brushes & Felt Bob & Burmandrels

- Polishing Brush & Wheel In Bristle Cotton Cloth

- Felt Bobs & Burs

- Hard Z Cutter

- Sharpening Stones

- Cleaning Brushes By Hand

- Stainless Steel Discs

- Stone Disc

- Technician Kits

- Flexsoft Partial Denture

- Empty Aluminum Cartridge

- Twin-Color Diamond polishers

- Dental Porcelain Brushes

- About Us

- Blog

- Catalogs

- Contact Us