Welcome to our beginner's guide to tungsten carbide burs! If you're new to the world of cutting and shaping materials, don't worry – we won't judge. In fact, we're here to help you get up to speed on one of the most important tools in any craftsman's arsenal: the tungsten carbide bur.

Now, you might be thinking, "Tungsten carbide bur? That sounds like a fancy dental tool." And you wouldn't be wrong – tungsten carbide burs are indeed essential tools for dentists. But they're also used in a variety of other fields, from jewelry-making to metalworking to woodworking.

We'll keep things professional, but don't worry – we'll throw in a joke or two to keep things light. So sit back, relax, and get ready to become a tungsten carbide bur pro!

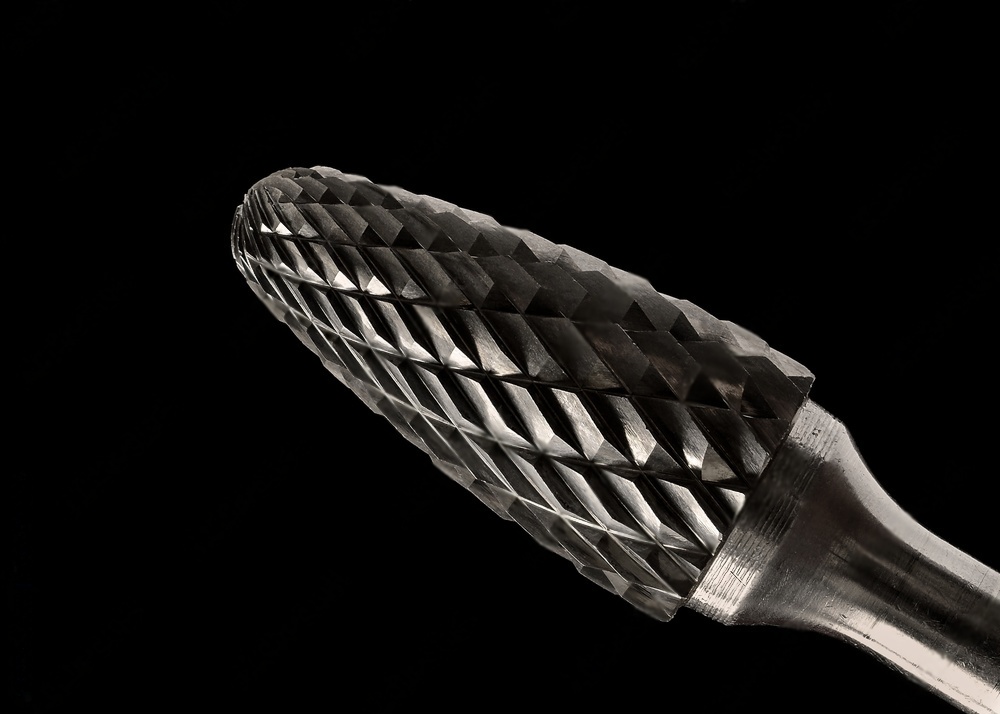

First things first: what is tungsten carbide? It sounds like something out of a sci-fi movie, but it's actually pretty common material. Tungsten carbide is a composite material made up of tungsten carbide particles and a binding agent, usually cobalt. The result is a super-hard material that's perfect for cutting and shaping tough materials like metals and ceramics.

"I recommend new users start with cylinder-shaped tungsten carbide burs and take it slow," says Michelle, a jewelry maker. "They're the most versatile and forgiving as you get the hang of things."

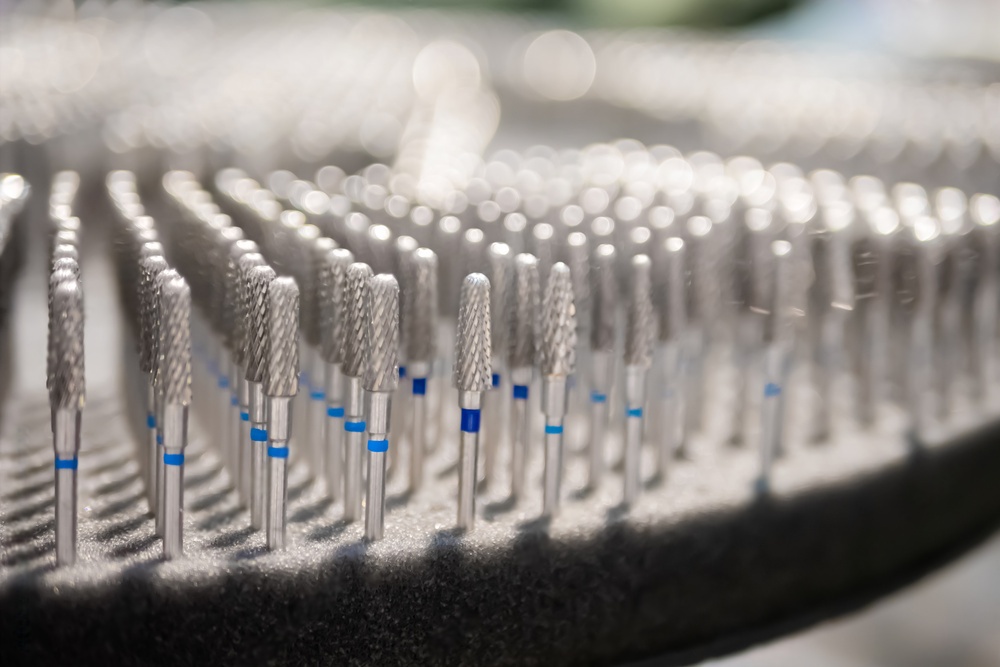

So, what are tungsten carbide burs?

Simply put, they're small rotary cutting tools that are used to shape and remove material from a workpiece. They come in a variety of shapes and sizes, from cylindrical to spherical to flame-shaped. Each shape is designed to be used for a specific purpose, so it's important to choose the right one for the job.

Now, let's talk about how to use tungsten carbide burs.

First, you'll need a rotary tool, such as a Dremel or a dental handpiece. Insert the bur into the tool and tighten it securely. Then, turn on the tool and gently bring the bur into contact with the workpiece. Apply light pressure and let the bur do the work. Don't push too hard or you could damage the bur or the workpiece.

One important thing to keep in mind when using tungsten carbide burs is that they generate a lot of heat. This can be dangerous if you're not careful. Make sure to wear eye protection and gloves, and work in a well-ventilated area. If you're working on a delicate or heat-sensitive material, you may need to use a lubricant or coolant to keep the temperature down.

In conclusion, tungsten carbide burs are versatile and essential tools for anyone working in a field that requires precision cutting and shaping. With the right tool and a little bit of practice, you can achieve professional-level results. So go ahead, give tungsten carbide burs a try, you might just be surprised at what you can create!