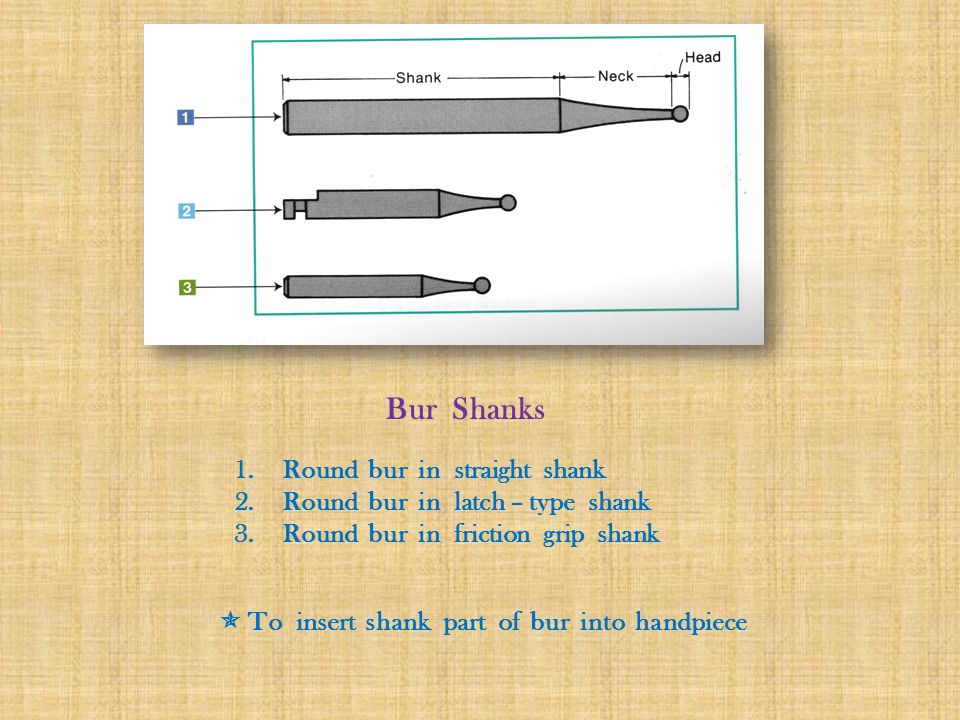

All burs are made up of a head and a shank, parts of burs also include the necks. Just as there are different shapes of the heads, shanks also have different shapes of the end to attach to different types of handpieces. They are also made of stainless-steel material.

Here show you three main types of the shanks: Long Straight Shank (HP), Right Angle (RA), also known as Latch-type, and Friction Grip (FG)

You can see it more visually from the image:

Here are three points that will give you a clearer understanding of the different types of shanks and help you to quickly select the suitable one you need to use.

First, the standard length

Long Straight Shank (HP) and Latch-type/ Right Angle Shank (RA)

These two types of shanks are generally 20mm in length with a 2.35mm diameter.

And RA is available in the same shape as FG.

Friction Grip Shank (FG)

The standard length of this type of shank is 20mm long with a 1.6mm diameter.

However, depending on the shank length, short shanks (FGSS) and long surgical lengths (FGOS) are also available.

Second, the applications of three shank types

Long Straight Shank (HP) can be used in both the clinic and laboratory. For example, the main use of Diamond Burs HP in laboratory is to grind or polish Ceramics. And Tungsten Carbide Burs HP can cut sharply.

Latch-type/ Right Angle Shank (RA) is used in providing greater control when cutting dentin or enamel.

Friction Grip Shank (FG) commonly used in operative burs in many offices.

FGSS, it is better access to the posterior when is needed, especially when patients

cannot open their mouth widely enough.

FGOS, often used when a longer length and better visibility are required, including in extraction and root canal procedures.

Third, they are suitable for which dental handpiece

1.Larger, long straight shanks fit into the nose cone of the slow speed handpiece.

2.Latch-type/ Right Angle (RA) shanks fit into the latch of the contra-angle on a low-speed handpiece.

3.Friction grip (FG) shanks fit into the turbine of a high-speed handpiece; Chuck, lever, or push button tightens bur into the handpiece.