Abrasive tools are essential for professionals in the dental, jewelry, and other industries who work with hard materials. Two of the most commonly used abrasive tools are carbide burs and diamond burs, but they have significant differences in terms of their composition, performance, and cost. In this blog post, we'll explore these differences to help you make an informed decision about which type of abrasive tool is right for your specific needs.

Composition and Availability

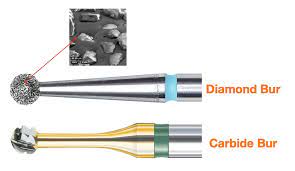

Carbide burs are made from tungsten carbide, a hard and durable material that is ideal for cutting softer materials like acrylics, composites, and some metals. Carbide burs are available in a variety of shapes and sizes, making them versatile and useful for a wide range of tasks. However, carbide burs are generally more expensive than diamond burs.

Diamond burs, on the other hand, are made with synthetic diamonds and are incredibly hard and durable. They are ideal for grinding hard materials like enamel, ceramics, and some metals. Diamond burs are available in a range of grits and shapes, making them an excellent choice for precision grinding, cutting, and shaping, as well as polishing restorations.

Performance

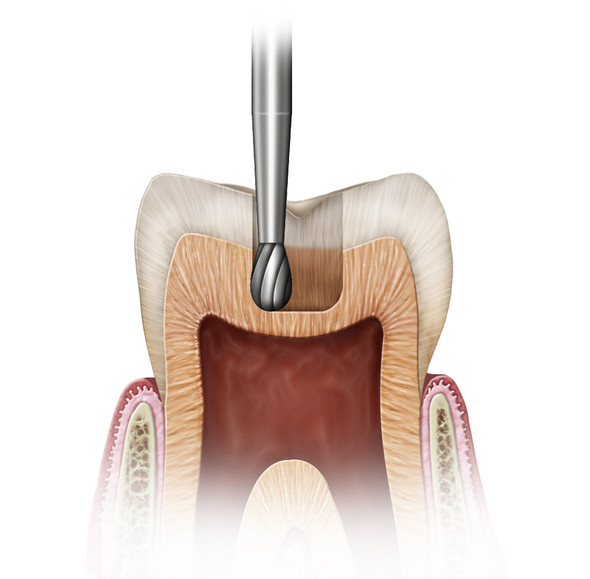

One of the advantages of carbide burs is their excellent cutting performance in removing soft or decayed tooth material and shaping restorations. They are designed with sharp blades that cut through the material quickly and efficiently.

Diamond burs, on the other hand, are renowned for their precision grinding and shaping abilities. Diamond burs create less heat and vibration during use, making them more comfortable for the patient and the professional. With diamond burs, there is also a reduced risk of damaging the inner pulp area of the tooth.

Cost

The cost of abrasive tools is an important consideration for professionals. Carbide burs are generally more expensive than diamond burs, but they are a worthwhile investment for professionals who work with soft materials and need a tool that can provide precise cuts and a long lifespan.

Usages

Both tungsten carbide burs and diamond burs can be utilized for deburring, finishing, smoothing, and shaping. However, carbide burs are more resistant to high temperatures than other materials, allowing them to operate for longer periods. Diamond burs are more useful for grinding into hard materials like enamel and ceramics, making them ideal for tasks like carving into stone.

Durability

Both diamond and carbide are exceptionally durable substances. However, diamond burs lose cutting effectiveness more dramatically than carbide burs over time, resulting in a shorter lifespan. Carbide burs have a longer lifespan than diamond burs, making them a cost-effective option for professionals who use abrasive tools frequently.

Smoothness

Carbide burs cut and chip away the tooth structure, resulting in a smoother finish than diamond burs, which grind the tooth structure. However, in some cases, a smoother finish may not be necessary or desired, and a rougher surface created by diamond burs may provide better adhesion for restorative materials.

Zirconia Cutting Burs

Cutting and removing zirconia crowns can be rather difficult. Diamond burs are more suitable for the task than carbide burs due to their high-speed grind. The same remains good for ceramic crown fabrication.

Choosing the Right Tool

So, which one is right for you? It depends on the specific task you need to perform and the material you're working with. If you're working with softer materials, carbide burs may be the better choice for cutting and shaping. If you're working with hard materials like enamel and ceramics, diamond burs may be the way to go for grinding and shaping. It's also important to consider your budget, the frequency of use, the speed of the abrasive tool, and the desired finish when selecting a tool.

Conclusion

In conclusion, both carbide burs and diamond burs have their strengths and weaknesses. By considering the specific task you need to perform and the material you're working with, you can choose the right abrasive tool for your needs. It's important to weigh the pros and cons of each tool, including precision, durability, usages, smoothness, and cost, to make an informed decision.

And if you're still not sure, don't hesitate to contact B&D Technologies for guidance and support. We will help you find the perfect abrasive tool for your specific needs, whether you're a dental professional, jeweler, or other professional who needs to work with hard materials. By choosing the right abrasive tool, you can ensure a successful outcome for your project and provide the best possible results for your clients or patients.